RFID Basics: What It Is & Why It Matters

Understand the fundamentals of RFID technology and why it’s revolutionizing DoD inventory management.

How RFID Works

A Typical UHF RFID System

Inventory Computer

Controls all RFID readers in system and keeps track of all items in inventory in real time.

RFID Reader

Sends and receives RF signals from antenna and extracts RFID tag numbers.

Antenna

Radiates and receives RF energy over a specified coverage area.

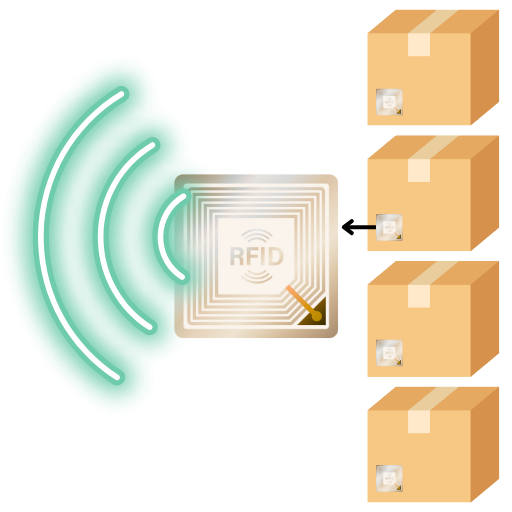

RFID Tag

Reflects the transmitted signal with a coded modulation unique to the tag. Powered by transmitted RF energy.

- A single inventory computer may control many RFID readers simultaneously.

- Each reader may control up to four antennas independently.

- A very large number of RFID tags may be read simultaneously by one reader.

Key RFID Benefits

Reads 700–1000 Tags/Sec

Process inventory faster than ever

100% Accuracy

Eliminate human error from manual counts

No Line-of-Sight Needed

Tags read through boxes, racks, and more

RFID vs. Barcode Technology

| Feature | RFID | Barcode |

|---|---|---|

| Line of Sight | ❌ Not Required | ✅ Required |

| Read Rate | 🔄 700–1000 tags/sec | 🐌 One at a time |

| Accuracy | ✅ Near 100% | ⚠️ Prone to human error |

| Inventory Time | ⏱ 95% faster | 🕓 Time-consuming |

| Automation Ready | ✅ Fully Automated | ❌ Manual Scanning Needed |

Choose the Right Solution for Your Operation

From high-volume warehouses to remote field deployments, our RFID systems deliver unmatched accuracy, speed, and reliability.